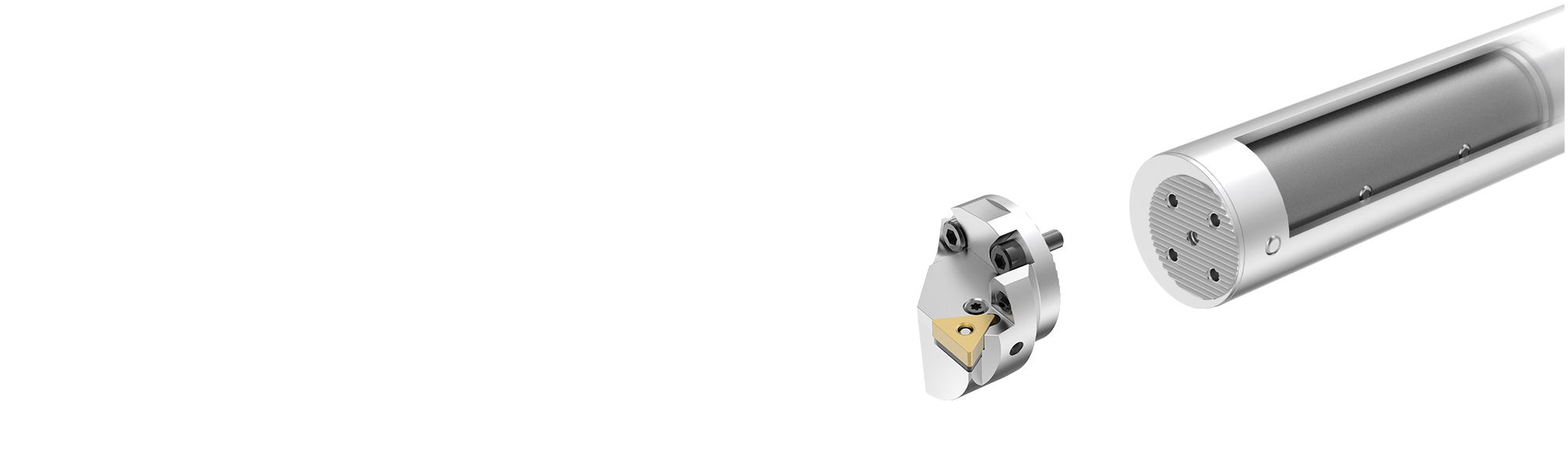

Modulare Bohrstangen mit verzahnter Schnittstelle

Bei diesen Bohrstangen kommt ein neues Sortiment von anschraubbaren Schneidköpfen zum Einsatz, die durch eine Verzahnung charakterisiert sind.

- Kurze anschraubbare Schneidköpfe sorgen für geringes Gewicht, hohe Stabilität und konstante Wiederholgenauigkeit.

- Die verzahnte Schnittstelle bietet höhere Verbindungsstärke und ermöglicht eine höhere Genauigkeit der Wendeschneidplattenpositionierung.

- Vibrationsfreie Bohrstangen bieten Stabilität und Steifigkeit beim Ausdrehen mit Auskragungen bis zu 10 x D.

- Vibrationsfreie Bohrstangen sind eine Plug-and-Play-Lösung, die für den sofortigen Einsatz entwickelt wurde, ohne dass eine manuelle Einstellung erforderlich oder möglich ist. Das interne Dämpfungssystem gewährleistet Prozessstabilität durch die erhöhte Steifigkeit der Bohrstange und die Dämpfung von Rattern.